Bolt Ceann Heicseagánach HDG DIN933 Galbhánaithe Tumtha Te

Bolt Ceann Heicseagánach HDG DIN933 Galbhánaithe Tumtha Te

Cur síos

MEARFreagra

MEARLuachan

MEARSeachadadh

RÉIDH LE SEACHADADH

10000+ SKU sa stóras

Táimid tiomanta do mhíreanna RTS:

70% earraí seachadta laistigh de 5 lá

80% earraí seachadta laistigh de 7 lá

90% earraí seachadtalaistigh de 10 lá

Orduithe mórchóir, déan teagmháil le seirbhís do chustaiméirí

| d | M1.6 | M2 | M2.5 | M3 | (M3.5) | M4 | M5 | M6 | (M7) | M8 | M10 | M12 | (M14) | M16 | |||||||||||||||||

| P | Páirc | 0.35 | 0.4 | 0.45 | 0.5 | 0.6 | 0.7 | 0.8 | 1 | 1 | 1.25 | 1.5 | 1.75 | 2 | 2 | ||||||||||||||||

| a | Uasmhéid | 1.05 | 1.2 | 1.35 | 1.5 | 1.8 | 2.1 | 2.4 | 3 | 3 | 3.75 | 4.5 | 5.25 | 6 | 6 | ||||||||||||||||

| c | Min | 0.1 | 0.1 | 0.1 | 0.15 | 0.15 | 0.15 | 0.15 | 0.15 | 0.15 | 0.15 | 0.15 | 0.15 | 0.15 | 0.2 | ||||||||||||||||

| Uasmhéid | 0.25 | 0.25 | 0.25 | 0.4 | 0.4 | 0.4 | 0.5 | 0.5 | 0.5 | 0.6 | 0.6 | 0.6 | 0.6 | 0.8 | |||||||||||||||||

| da | Uasmhéid | 2 | 2.6 | 3.1 | 3.6 | 4.1 | 4.7 | 5.7 | 6.8 | 7.8 | 9.2 | 11.2 | 13.7 | 15.7 | 17.7 | ||||||||||||||||

| dw | Rang A | Min | 2.4 | 3.2 | 4.1 | 4.6 | 5.1 | 5.9 | 6.9 | 8.9 | 9.6 | 11.6 | 15.6 | 17.4 | 20.5 | 22.5 | |||||||||||||||

| Rang B | Min | - | - | - | - | - | 5.7 | 6.7 | 8.7 | 9.4 | 11.4 | 15.4 | 17.2 | 20.1 | 22 | ||||||||||||||||

| e | Rang A | Min | 3.41 | 4.32 | 5.45 | 6.01 | 6.58 | 7.66 | 8.79 | 11.05 | 12.12 | 14.38 | 18.9 | 21.1 | 24.49 | 26.75 | |||||||||||||||

| Rang B | Min | - | - | - | - | - | 7.5 | 8.63 | 10.89 | 11.94 | 14.2 | 18.72 | 20.88 | 23.91 | 26.17 | ||||||||||||||||

| k | Ainmniúil | 1.1 | 1.4 | 1.7 | 2 | 2.4 | 2.8 | 3.5 | 4 | 4.8 | 5.3 | 6.4 | 7.5 | 8.8 | 10 | ||||||||||||||||

| Rang A | Min | 0.98 | 1.28 | 1.58 | 1.88 | 2.28 | 2.68 | 3.35 | 3.85 | 4.65 | 5.15 | 6.22 | 7.32 | 8.62 | 9.82 | ||||||||||||||||

| Uasmhéid | 1.22 | 1.52 | 1.82 | 2.12 | 2.52 | 2.92 | 3.65 | 4.15 | 4.95 | 5.45 | 6.56 | 7.68 | 8.98 | 10.18 | |||||||||||||||||

| Rang B | Min | - | - | - | - | - | 2.6 | 3.26 | 3.76 | 4.56 | 5.06 | 6.11 | 7.21 | 8.51 | 9.71 | ||||||||||||||||

| Uasmhéid | - | - | - | - | - | 3 | 3.74 | 4.24 | 5.04 | 5.54 | 6.69 | 7.79 | 9.09 | 10.29 | |||||||||||||||||

| k1 | Min | 0.7 | 0.9 | 1.1 | 1.3 | 1.6 | 1.9 | 2.28 | 2.63 | 3.19 | 3.54 | 4.28 | 5.05 | 5.96 | 6.8 | ||||||||||||||||

| r | Min | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.2 | 0.2 | 0.25 | 0.25 | 0.4 | 0.4 | 0.6 | 0.6 | 0.6 | ||||||||||||||||

| s | Uasmhéid=Ainmniúil | 3.2 | 4 | 5 | 5.5 | 6 | 7 | 8 | 10 | 11 | 13 | 17 | 19 | 22 | 24 | ||||||||||||||||

| Rang A | Min | 3.02 | 3.82 | 4.82 | 5.32 | 5.82 | 6.78 | 7.78 | 9.78 | 10.73 | 12.73 | 16.73 | 18.67 | 21.67 | 23.67 | ||||||||||||||||

| Rang B | Min | - | - | - | - | - | 6.64 | 7.64 | 9.64 | 10.57 | 12.57 | 16.57 | 18.48 | 21.16 | 23.16 | ||||||||||||||||

| d | (M18) | M20 | (M22) | M24 | (M27) | M30 | (M33) | M36 | (M39) | M42 | (M45) | M48 | (M52) | ||||||||||||||||||

| P | Páirc | 2.5 | 2.5 | 2.5 | 3 | 3 | 3.5 | 3.5 | 4 | 4 | 4.5 | 4.5 | 5 | 5 | |||||||||||||||||

| a | Uasmhéid | 7.5 | 7.5 | 7.5 | 9 | 9 | 10.5 | 10.5 | 12 | 12 | 13.5 | 13.5 | 15 | 15 | |||||||||||||||||

| c | Min | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 | |||||||||||||||||

| Uasmhéid | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 1 | 1 | 1 | 1 | 1 | ||||||||||||||||||

| da | Uasmhéid | 20.2 | 22.4 | 24.4 | 26.4 | 30.4 | 33.4 | 36.4 | 39.4 | 42.4 | 45.6 | 48.6 | 52.6 | 56.6 | |||||||||||||||||

| dw | Rang A | Min | 25.3 | 28.2 | 30 | 33.6 | - | - | - | - | - | - | - | - | - | ||||||||||||||||

| Rang B | Min | 24.8 | 27.7 | 29.5 | 33.2 | 38 | 42.7 | 46.5 | 51.1 | 55.9 | 59.9 | 64.7 | 69.4 | 74.2 | |||||||||||||||||

| e | Rang A | Min | 30.14 | 33.53 | 35.72 | 39.98 | - | - | - | - | - | - | - | - | - | ||||||||||||||||

| Rang B | Min | 29.56 | 32.95 | 35.03 | 39.55 | 45.2 | 50.85 | 55.37 | 60.79 | 66.44 | 71.3 | 76.95 | 82.6 | 88.25 | |||||||||||||||||

| k | Ainmniúil | 11.5 | 12.5 | 14 | 15 | 17 | 18.7 | 21 | 22.5 | 25 | 26 | 28 | 30 | 33 | |||||||||||||||||

| Rang A | Min | 11.28 | 12.28 | 13.78 | 14.78 | - | - | - | - | - | - | - | - | - | |||||||||||||||||

| Uasmhéid | 11.72 | 12.72 | 14.22 | 15.22 | - | - | - | - | - | - | - | - | - | ||||||||||||||||||

| Rang B | Min | 11.15 | 12.15 | 13.65 | 14.65 | 16.65 | 18.28 | 20.58 | 22.08 | 24.58 | 25.58 | 27.58 | 29.58 | 32.5 | |||||||||||||||||

| Uasmhéid | 11.85 | 12.85 | 14.35 | 15.35 | 17.35 | 19.12 | 21.42 | 22.92 | 25.42 | 26.42 | 28.42 | 30.42 | 33.5 | ||||||||||||||||||

| k1 | Min | 7.8 | 8.5 | 9.6 | 10.3 | 11.7 | 12.8 | 14.4 | 15.5 | 17.2 | 17.9 | 19.3 | 20.9 | 22.8 | |||||||||||||||||

| r | Min | 0.6 | 0.8 | 0.8 | 0.8 | 1 | 1 | 1 | 1 | 1 | 1.2 | 1.2 | 1.6 | 1.6 | |||||||||||||||||

| s | Uasmhéid=Ainmniúil | 27 | 30 | 32 | 36 | 41 | 46 | 50 | 55 | 60 | 65 | 70 | 75 | 80 | |||||||||||||||||

| Rang A | Min | 26.67 | 29.67 | 31.61 | 35.38 | - | - | - | - | - | - | - | - | - | |||||||||||||||||

| Rang B | Min | 26.15 | 29.16 | 31 | 35 | 40 | 45 | 49 | 53.8 | 58.8 | 63.1 | 68.1 | 73.1 | 78.1 | |||||||||||||||||

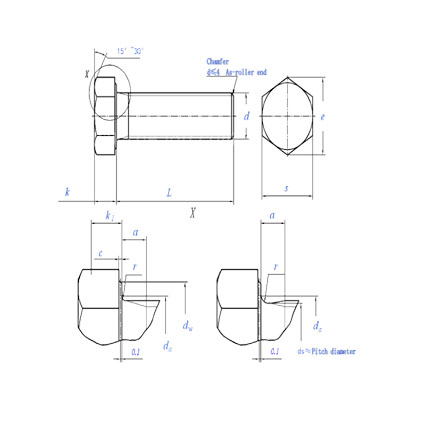

Líníocht mhionsonraithe

De ghnáth, tagraíonn HDG do ghalbhánú tumtha te. Is éard atá i ngalbhánú tumtha te ná an miotal leáite a imoibriú leis an maitrís iarainn chun ciseal cóimhiotail a tháirgeadh, ionas go gcomhcheanglaítear an maitrís agus an sciath. Is éard atá i ngalbhánú tumtha te ná na codanna iarainn agus cruach a phicilte ar dtús, chun an ocsaíd iarainn a bhaint de dhromchla na gcodanna iarainn agus cruach, tar éis picilte, déantar é a ghlanadh i dtuaslagán uiscí clóiríd amóiniam nó clóiríd since nó i dtuaslagán uiscí measctha de chlóiríd amóiniam agus clóiríd since, agus ansin seoltar chuig an umar sciath tumtha te é. Tá na buntáistí a bhaineann le galbhánú tumtha te sciath aonfhoirmeach, greamaitheacht láidir agus saolré seirbhíse fada.

Is é tiús an tsraithe ghalbhánuithe a chinneann an fhriotaíocht creimeadh den chuid is mó, mar sin is minic gurb é an tomhas tiús an príomhbhunús chun cáilíocht an tsraithe ghalbhánuithe a mheas. Bíonn tionchar mór ag uillinn agus luas an tuaslagáin freisin. Dá bhrí sin, is beagnach dodhéanta tiús sciath aonfhoirmeach a fháil. Dá bhrí sin, ní féidir tomhas an mhéid greamaitheachta a mheas riamh le pointe (suíomh) aonair. Níl aon bhrí leis ach an meánmheáchan greamaitheachta (g) in aghaidh an aonaid achar (㎡) a thomhas. Tá go leor modhanna ann chun an méid greamaitheachta a thomhas, amhail modh breathnóireachta miotalagrafaíochta rannóige millteach, modh picilte, modh méadair tiús scannáin neamh-millteach, modh leictriceimiceach, modh meastacháin ar an difríocht meáchain idir earraí isteach agus amach, etc. Is iad na modhanna a úsáidtear go coitianta ná an modh tomhais tiús scannáin agus an modh picilte.

Pacáil

Cuirimid réimse leathan pacáistíochta ar fáil chun freastal ar thimpeallachtaí loingseoireachta agus rialú costais éagsúla. Is iad na cineálacha pacáistíochta is coitianta ná pacáistí tonna, málaí fite, boscaí i mbulc, boscaí i mboscaí, móide pailléid nó cásanna adhmaid chun freastal ar riachtanais iompair farraige nó aeir. Seo thíos grianghraif de na cineálacha éagsúla pacáistíochta a chuirimid ar fáil mar thagairt.

Fúinn

* Sainaithnítear na téarmaí trádála éagsúla sa léaráid seo a leanas. Roghnaigh an ceann is fearr leat.

TÁIRGE TE-DÍOLTA

Cáilíocht ar dtús, Sábháilteacht Ráthaithe